Page 12 - RCM - A Practical Guide

P. 12

RCM - A Practical Guide

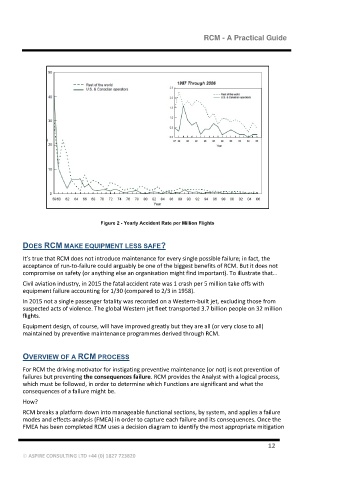

Figure 2 - Yearly Accident Rate per Million Flights

DOES RCM MAKE EQUIPMENT LESS SAFE?

It’s true that RCM does not introduce maintenance for every single possible failure; in fact, the

acceptance of run-to-failure could arguably be one of the biggest benefits of RCM. But it does not

compromise on safety (or anything else an organisation might find important). To illustrate that…

Civil aviation industry, in 2015 the fatal accident rate was 1 crash per 5 million take offs with

equipment failure accounting for 1/30 (compared to 2/3 in 1958).

In 2015 not a single passenger fatality was recorded on a Western-built jet, excluding those from

suspected acts of violence. The global Western jet fleet transported 3.7 billion people on 32 million

flights.

Equipment design, of course, will have improved greatly but they are all (or very close to all)

maintained by preventive maintenance programmes derived through RCM.

OVERVIEW OF A RCM PROCESS

For RCM the driving motivator for instigating preventive maintenance (or not) is not prevention of

failures but preventing the consequences failure. RCM provides the Analyst with a logical process,

which must be followed, in order to determine which Functions are significant and what the

consequences of a failure might be.

How?

RCM breaks a platform down into manageable functional sections, by system, and applies a failure

modes and effects analysis (FMEA) in order to capture each failure and its consequences. Once the

FMEA has been completed RCM uses a decision diagram to identify the most appropriate mitigation

12

© ASPIRE CONSULTING LTD +44 (0) 1827 723820